Stainless Steel Flanges

Home » Stainless Steel Flanges

Stainless Steel Flanges

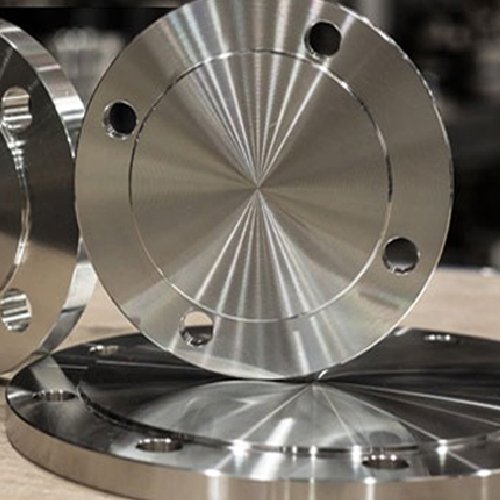

In the area of aerospace engineering, Meta Aerospace proudly stands as an optimal Stainless Steel Flanges manufacturer. With a legacy deeply rooted in precision craftsmanship and a steadfast commitment to quality, Meta Aerospace’s stainless steel flanges redefine reliability, structural integrity, and connectivity in aerospace programs.

What are Stainless Steel Flanges?

Stainless Steel Flanges from Meta Aerospace are vital additives designed to connect pipes, valves, pumps, and other equipment in aerospace fluid systems. These round discs with frivolously spaced bolt holes permit for the steady assembly and disassembly of different additives, making sure a leak-unfastened and green fluid waft inside aerospace structures.

| Flanges Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Flanges Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Flanges |

| Flanges Pressure in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Flanges |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Flanges |

| Flanges Manufacturing Method | Forged / Threaded / Screwed / Plate |

| Flanges Manufacturer in India | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. Flanges: -BS Flanges, EN Flanges, API 6A Flanges, ANSI Flanges, ASME Flanges, DIN Flanges, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange |

| Flanges Application |

|

| Material Forms | Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex Steel, Titanium, Hastelloy, High Nickel Alloy, etc. |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| JIS Flanges | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Flanges |

| UNI Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Flanges |

| EN Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Flanges |

| Connect Type/ Flanges Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Flanges Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal & Reducing Configurations |

| Type Of Test | Direct-reading Spectrograph, Hydrostatic Testing Machine, X-ray Detector, Ultrasonic Flaw Detector, Magnetic Particle Detector |

| Equipment Used | Press Machine, Bending Machine, Pushing Machine, Electric Bevelling Machine, Sand-Blasting Machine, etc. |

SS Flanges Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

Stainless Steel Pipe Flanges Specifications

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

- 9930066862

- Info@metaaerospaces.com

- Length: 500-10000

Importance of Stainless Steel Flanges?

The importance of Stainless Steel Flanges in aerospace packages lies of their vital attributes:

- Reliable Connectivity: Stainless Steel Flanges act as strong connectors in aerospace fluid systems, making sure a secure and reliable joint between diverse components. This reliability is vital for the overall overall performance and protection of aerospace structures.

- Corrosion Resistance: Stainless metallic, recognized for its corrosion-resistant residences, guarantees that the flanges hold their structural integrity even in corrosive aerospace environments. This corrosion resistance contributes to the longevity and reliability of fluid structures.

- Versatility: Stainless Steel Flanges cater to a numerous variety of aerospace packages, presenting a flexible solution for connecting pipes of different sizes and specifications. This adaptability is important for assembly of the varied necessities of aerospace fluid structures

Types of Stainless Steel Flanges

| Stainless Steel Slip On Flanges | SS Raised Face Slip On Flanges SS Slip On Plate Flanges Stainless Steel Slip On Flanges ASME SA182 Slip On Flanges |

| Stainless Steel Weld Neck Flanges | SS Raised Face Weld Neck Flanges SS Weld Neck Flanges Stainless Steel Weld Neck Flange ASTM A182 Stainless Steel WNRF Flange |

| Stainless Steel Blind Flanges | SS Raised Face Blind Flanges SS Blind Flanges Stainless Steel Blind Flange ASTM A182 304 Stainless Steel BLRF Flanges |

| Stainless Steel Orifice Flanges | SS Orifice Flanges Stainless Steel Orifice Flanges A182 304 Stainless Steel Orifice Flanges |

| Stainless Steel Socket weld Flanges | SS Socket weld Flanges Stainless Steel Socket weld Flanges ASME B16.5 Stainless Steel Socket weld Flanges |

| Stainless Steel Threaded Flanges | SS Threaded Flanges Stainless Steel Threaded Flanges ASTM A182 Stainless Steel Threaded Flanges |

| Stainless Steel Long weld Neck Flanges | SS Long weld Neck Flanges Stainless Steel Long weld Neck Flanges ASTM A182 304 Stainless Steel Long weld Neck Flanges |

| Stainless Steel RTJ Flanges | SS Ring Type Joint Flanges Stainless Steel RTJ Flanges BS4504 Stainless Steel 304 RTJ Flanges |

| Stainless Steel Reducing Flanges | SS Reducing Flanges Stainless Steel Reducing Flange ASTM A182 Stainless Steel 304 Reducing Flanges |

| Stainless Steel Forged Flanges | SS Forged Flanges Stainless Steel Forged Flange ASTM A182 Stainless Steel 304 Forged Flanges |

| Stainless Steel Spectacle Blind Flange | SS Spectacle Blind Flange Stainless Steel Spectacle Blind Flange ASTM A182 Stainless Steel 304 Spectacle Blind Flange |

| Stainless Steel Spade Flange | SS Spade Flange Stainless Steel Spade Flange ASTM A182 Stainless Steel 304 Spade Flange |

Stainless Steel Pipe Flanges Test Certificates

We at Meta Aerospace provide Manufacturer TC (Test Certificate) in accordance to EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirement like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

- EN 10204/3.1B,

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc

ASTM, ASME SS Flanges Value Added Services

Material Testing

We at Meta Aerospace ensure that all our materials go through strict quality tests before dispatching them to our clients.

- Mechanical Testing Such as Tensile of Area

- Hardness Test

- Chemical Analysis – Spectro Analysis

- Positive Material Identification – PMI Testing

- Flattening Test

- Micro and MacroTest

- Pitting Resistance Test

- Flaring Test

- Intergranular Corrosion (IGC) Test

Meta Aerospace as Stainless Steel Flanges supplier exemplifies the brand’s willpower to excellence in aerospace engineering. These components, with their reliable connectivity, corrosion resistance, and flexibility, stand as a testomony to Meta Aerospace’s commitment to supplying solutions that exceed industry requirements. Elevate your aerospace fluid systems with Meta Aerospace as Stainless Steel Flanges stockists – in which precision meets staying power for enduring aerospace excellence.