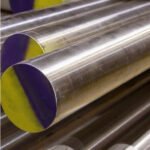

SS 17-4 PH Bar

Home » SS 17-4 PH Bar

SS 17-4 PH Bar

What is the SS 17-4 PH Bar?

Stainless Steel 17-4 PH Bar, regularly called SS 17-4 PH Bar, is a flexible and corrosion-resistant alloy renowned for its top-notch electricity and sturdiness. This material is precipitation-hardening martensitic chrome steel that exhibits stunning mechanical properties, making it a super choice for numerous worrying applications. The alloy consists of chromium, nickel, copper, and different elements, contributing to its unique mixture of strength, corrosion resistance, and ease of material.

We stand as a dependent source for the fantastic SS 17-4 PH Bar, presenting a fabric that combines power, corrosion resistance, and versatility. Whether you’re searching for a reliable SS 17-4 PH Bar manufacturer, a quality-stocked SS 17-4 PH Bar stockist, or a good SS 17-4 PH Bar dealer, we provide excellence in every product, ensuring the most fulfilling performance in vital applications.

Elevate your initiatives with our commitment to satisfactory innovation, counting on the durability and reliability of the SS 17-4 PH Bar for your maximum stressful requirements.

Applications of SS 17-4 PH Bar

- Aerospace Engineering

- Automotive Engineering

- Marine & Defense

- Oil & Gas

- Construction

- Chemical

- Cement

Specification Of Stainless Steel 17-4 PH Round Bars

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Grade | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Finish | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging, etc. |

| Form | 18mm – 57mm (11/16″ to 2-3/4″) |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Application | Chemical process, Food processing, Petrochemical, Pollution control, Pulp and Paper, Refining |

| Condition | Cold-drawn and Polished Cold-drawn centerless ground and polished. |

| Our 17-4 PH | Round Bars conform to NACE MR0175/ISO 15156. |

- 9930066862

- Info@metaaerospaces.com

- Length: 500-10000

Importance of SS 17-4 PH Bar

- High Strength and Hardness: The SS 17-4 PH Bar is celebrated for its splendid power and hardness, making it appropriate for packages in which strong overall performance is essential. It can face hard situations and heavy masses, ensuring long-lasting reliability.

- Corrosion Resistance: The alloy’s resistance to corrosion, coupled with its durability, makes it an extremely good choice for programs in corrosive environments. This feature is especially useful in industries that include aerospace, protection, and marine engineering.

- Versatility in Applications: SS 17-4 PH Bar reveals programs throughout diverse industries, consisting of aerospace, chemical processing, oil and gas, and more. Its versatility stems from its potential to hold mechanical properties across a huge variety of temperatures and environments.

- Ease of material: Our SS 17-4 PH Bar is designed to be machinable and weldable without difficulty, facilitating green material processes. This function enhances the cloth’s adaptability to various manufacturing necessities.

- Dimensional Stability: The alloy reveals incredible dimensional stability, minimizing the risk of distortion or deformation throughout processing and service. This is vital in programs where precision and consistency are paramount.

Types of SS 17-4 PH Bar

| Annealed Condition (Solution Annealed) | Softened structure for improved machinability and formability. |

| Aged Condition (Precipitation Hardened) | High strength and hardness achieved through precipitation hardening. |

| H900 Condition | Aging at approximately 900°F (482°C) for a balance of high strength and toughness. |

| H1025 Condition | Aging at approximately 1025°F (552°C) for a balance between strength and corrosion resistance. |

| H1075 Condition | Aging at around 1075°F (580°C) for high strength and excellent corrosion resistance. |

| H1150 Condition | Aging at approximately 1150°F (621°C) for a balance of strength and toughness. |

SS 17-4 PH Bar Test Certificates

We at Meta Aerospace provide Manufacturer TC (Test Certificate) in accordance with EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report. We also provide Standard certificates like EN 10204 3.1 and additional requirements like. NACE MR 01075. FERRIT CONTENT as per norms if requested by clients.

- EN 10204/3.1B,

- Raw Materials Certificate

- 100% Radiography Test Report

- Third Party Inspection Report, etc

If you have got any inquiries or require further information regarding our SS 17-4 PH Bars, rest assured that our committed team is poised to offer the help you need. As an outstanding SS 17-4 PH Bar manufacturer, stockist, and company, we prioritize purchaser pride, ensuring that you receive amazing guides and statistics.

Our dedication to excellence extends to our customer support, wherein we try to supply well timed and complete assistance. Whether you are seeking technical specs, pricing details, or preferred facts about our SS 17-4 PH Bars, crew our is prepared to deal with your queries with knowledge.

We apprehend the significance of clean conversation and reliable help. Our consumer-centric technique displays our dedication to ensuring that you have the greatest feasible level whilst coping with our SS 17-4 PH Bars. We cost your interest and assume serving you with the best requirements of provider and product quality.

Feel free to reach out to us for any statistics or help you require concerning Meta Aerospace’s SS 17-4 PH Bars. We are here to offer the guide and know-how you need on your particular applications.